Although orton pyrometric cones were developed in the late 1800 s to provide the ceramist with a tool to measure the firing of ceramic products cones have stood the test of time and continue to provide verification of the combined effect of time and temperature heatwork on ceramic products around the globe.

Ceramic orton cone definition.

In 1894 he was appointed the first chairman of the ceramic engineering department at the ohio state university the first ceramic engineering.

A properly fired cone will bend over with the tip of the cone almost touching the shelf.

The large and self supporting cones are used to measure temperature uniformity and or if there was sufficient heatwork done to mature the ware.

Orton pyrometric cones are dry pressed instead of plastic formed providing less variability in performance higher green strength and fewer mounting problems.

Orton was a pioneer in developing and applying scientific principles to ceramic manufacturing.

They are not simple temperature measuring devices.

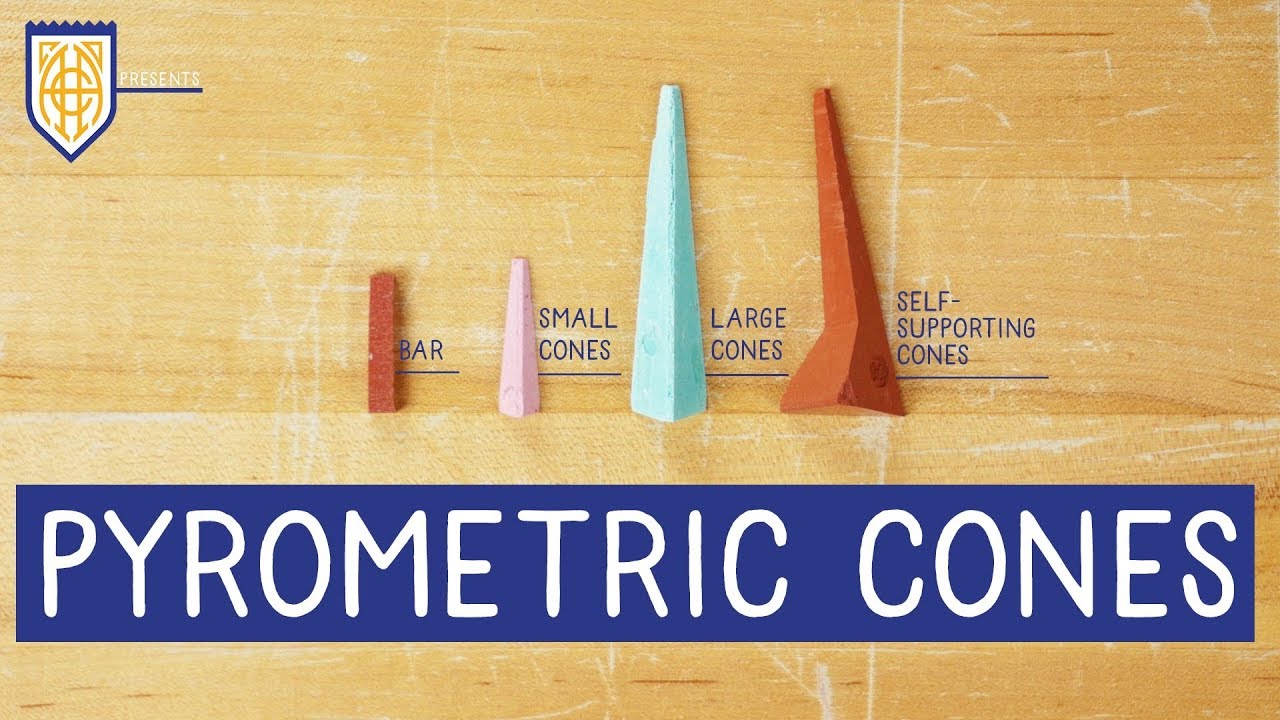

The pyrometric cone is described by dodd and murfin 1994 as a pyramid with a triangular base and of a defined shape and size.

This deforming action allows the kiln to shut off automatically at the proper point as in the case of the mini bar and kiln sitter or simply to record what happened during the firing as in the case of the witness cone.

The cone is shaped from a carefully proportioned and uniformly mixed batch of ceramic materials so that when it is heated under stated conditions it will bend due to softening the tip of the cone becoming level with the base at a definitive temperature.

Thus pyrometric cones give a temperature equivalent.

Pyrometric cones are pyrometric devices that are used to gauge heatwork during the firing of ceramic materials.

Materials are mixed sampled and test cones made and fired on defined heating rates with standard cones.

Your ceramic ware provider can provide guidance on which cone to fire to for your specific ware.

Cones indicate whether the ware received an adequate amount of heatwork to properly mature the clay or glaze.

All cone batches made by orton are tested to match established standards.

The roots of the orton ceramic foundation date back to the establishment of the standard pyrometric cone company in 1896 by dr.