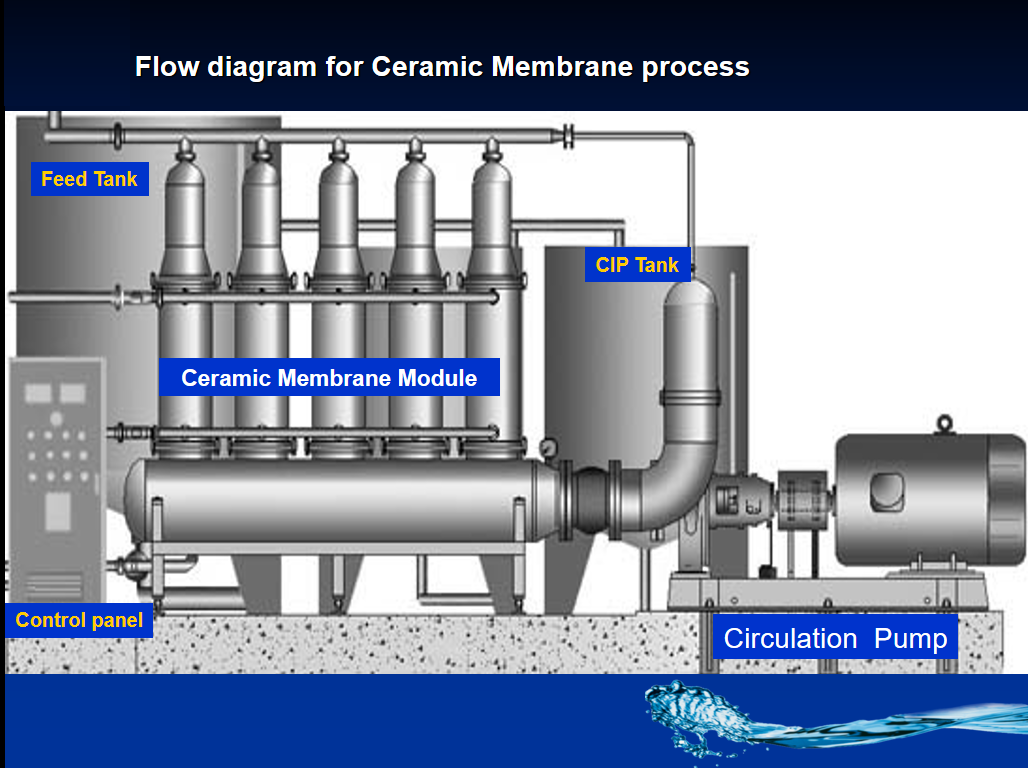

The ceramic membrane was equipped with a feed tank having a working volume of 600 ml the pressures before and after the membrane module were read from the pressure gauges installed at the inlet and outlet of modules.

Ceramic membrane mollases.

As listed in table s2 the ceramic membrane filtration does not produce a considerable sugar loss and color removal while it can eliminate all the suspended solids.

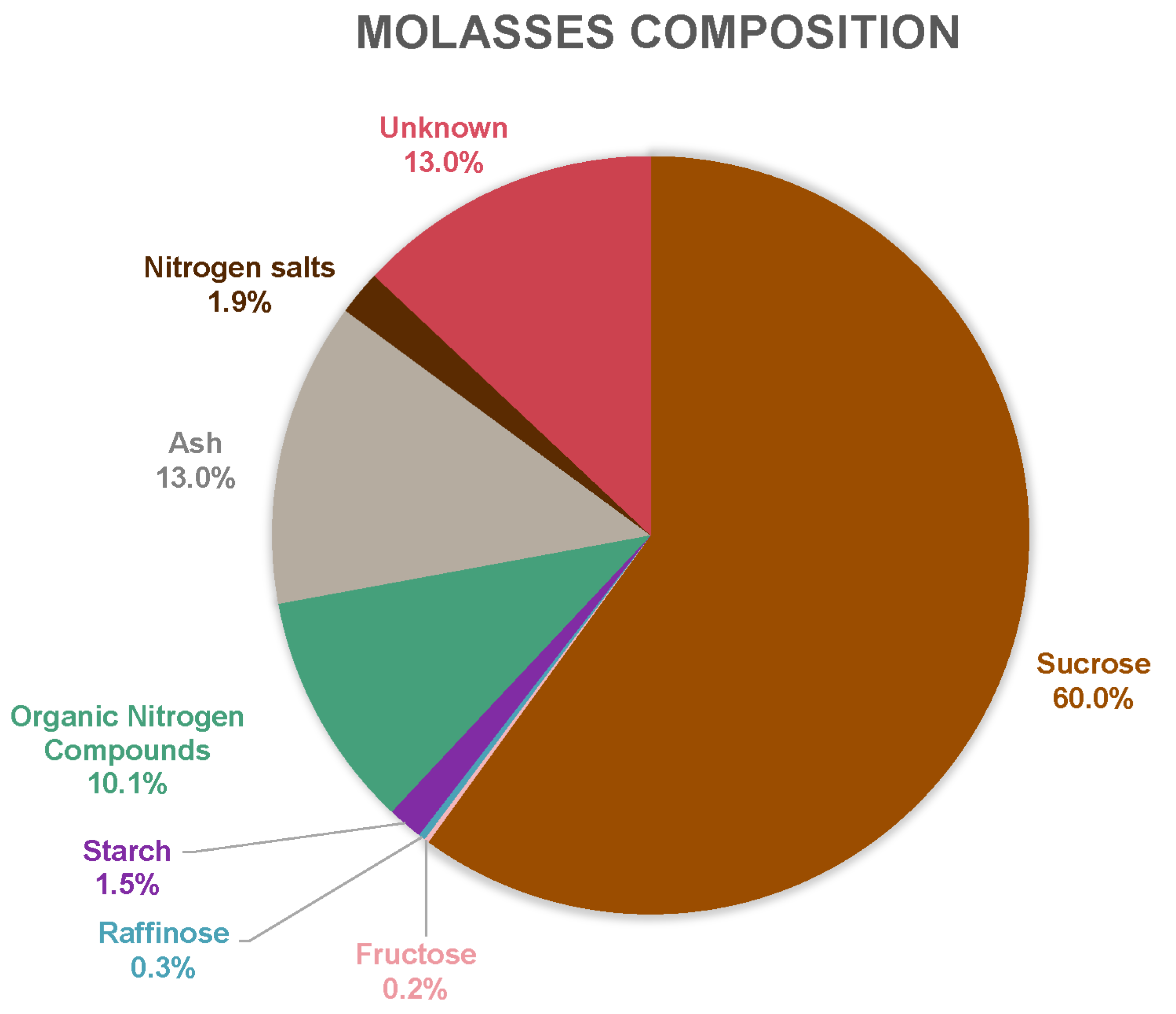

Membrane technology provides a green approach to recover sucrose from cane molasses.

The home made apparatus equipped with ceramic and polymeric membranes were used for pretreatment and purification of molasses respectively.

Membrane lc1 was the most adequate to reach the project objective presenting high permeate fluxes and high levels of sucrose retention.

An observed color reduction in treated molasses was caused by the removal of ash and a large amount of coloring matters.

While the acidic cleaning could almost remove the remaining fouling indicating that the inorganic fouling played an important role in the molasses filtration by the ceramic membrane.

However the trade off between color removal and sucrose permeation by membrane filtration debases the.

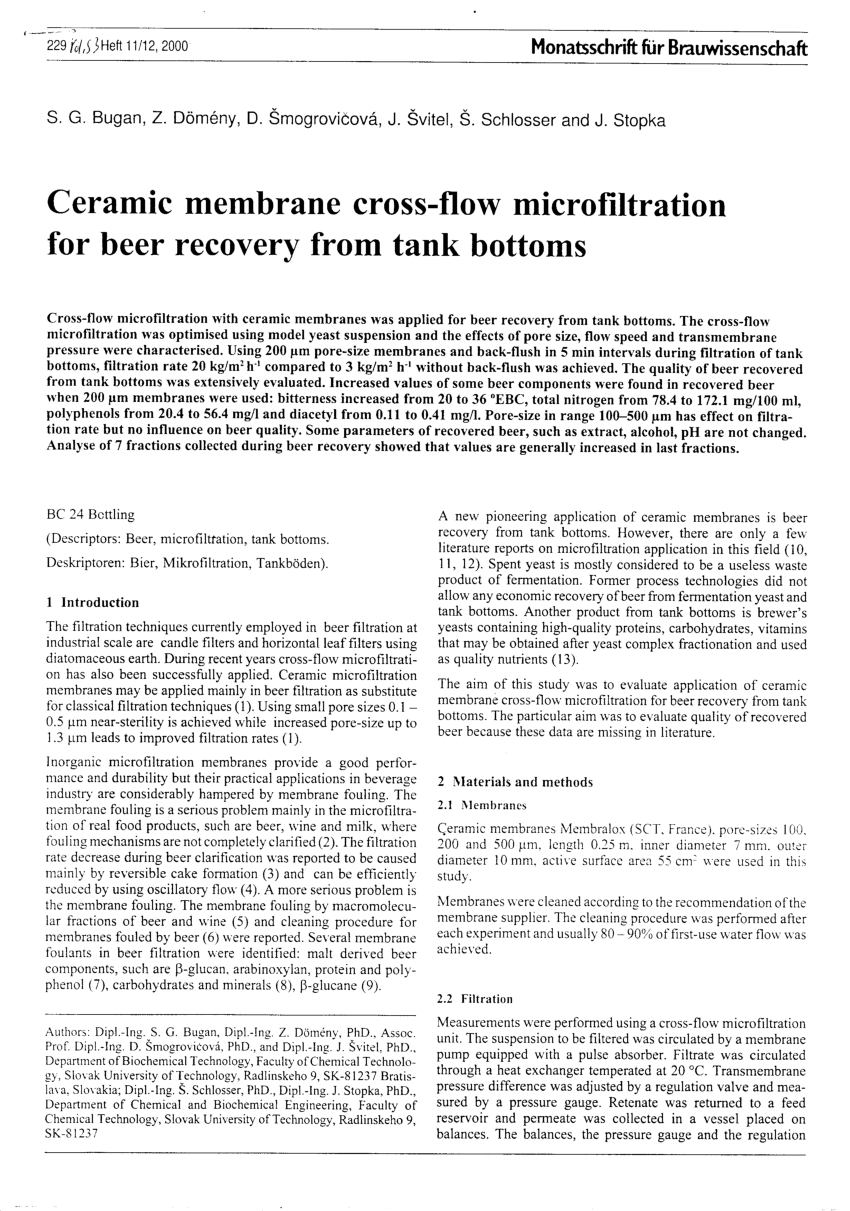

Ceramic membranes are a type of artificial membranes made from inorganic materials such as alumina titania zirconia oxides silicon carbide or some glassy materials.

They are used in membrane operations for liquid filtration.

Most ceramic membranes are made of alumina titania silica zirconia or mixture of these materials 93 the basic structure of ceramic membranes consists of a macroporous support layer and meso or microporous active layer.

Zhe yang chuyang y.

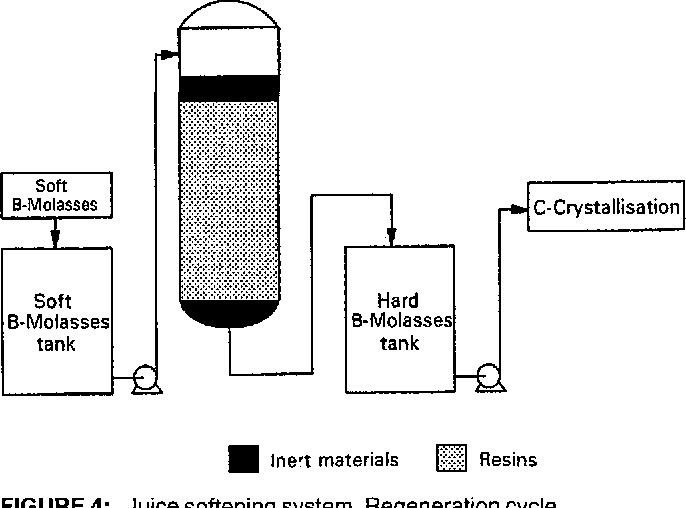

To evaluate the performance of a nanofiltration process using ceramic membranes to recover sucrose from sugar beet molasses.

Two membranes with mwco of 200 and 350 da were tested under different operating conditions.