The tensile testing of sic and sic tib2 composites exhibits 55 and 79 failures respectively in the gage section with possible further improvements.

Ceramic materials tensile test.

The nondestructive testing ndt techniques employed for the testing of monolithic ceramic materials and ceramic matrix composites to promote the application of engineering ceramics is discussed.

Small displacements correspond to large force increases for ceramic materials so machine actuators and controls must be able to apply this increasing force without significant oscillation around the desired force caused by crosshead vibration.

Average tensile strength values of 160 and.

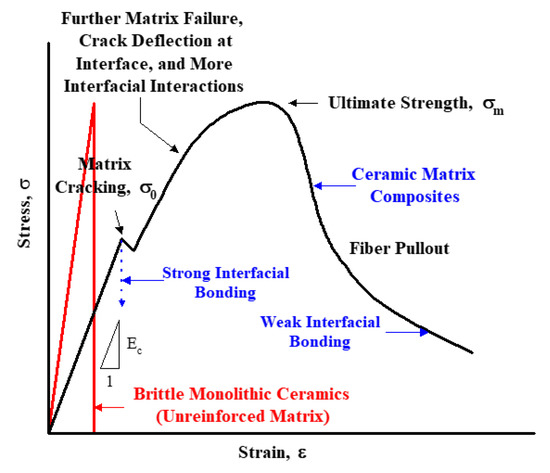

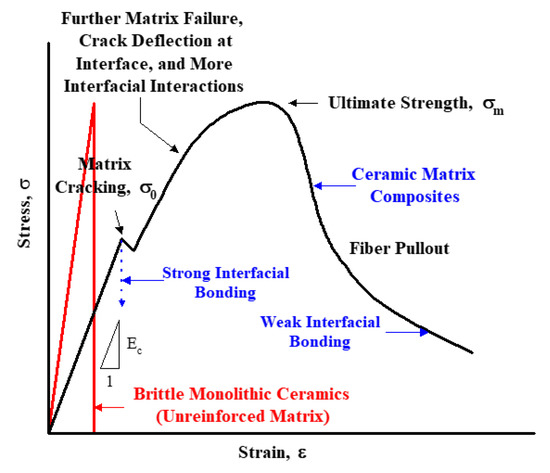

Because of the way that ceramics are constructed they generally posses vary high compressive strengths and will most often fail due to tensile flexural or fracture forces.

The tests can be performed by three or four point bending tests.

Another accepted method of evaluating the mechanical properties of a ceramic is by a bending flexural test.

4 7 the tensile strength of a ceramic material is dependent on both its inherent resistance to fracture and the presence of flaws.

Test machines for ceramic tensile testing must have a high force capacity.

Tensile testing of ceramics video gauge tm has no problem reading strains for ceramics without any damage to the surface the small elongations can be accurately measured over short testing periods to give reliable results through the absence of surface scratches high temperature testing is also possible with only line of sight to the specimen required to take measurements video gauge benefits can include.

There are many different tests that can be performed upon ceramics but the most common and important are those that involve compression tension flexural and fracture mechanics.

Analysis of fracture surfaces and fractography though beyond the scope of this test method is highly recommended for all purposes especially for design data.

In addition test specimen fabrication methods testing modes force displacement or strain control testing rates force.

We have collected a number of charts detailing applications and properties for some of the most commonly used ceramic materials.

1 1 this test method covers the determination of tensile strength under uniaxial loading of monolithic advanced ceramics at elevated temperatures.

While the data in these charts is in most cases typical of what you will find from ceramic component suppliers it is only intended to be a general point of reference and should not be used for material selection or specification.