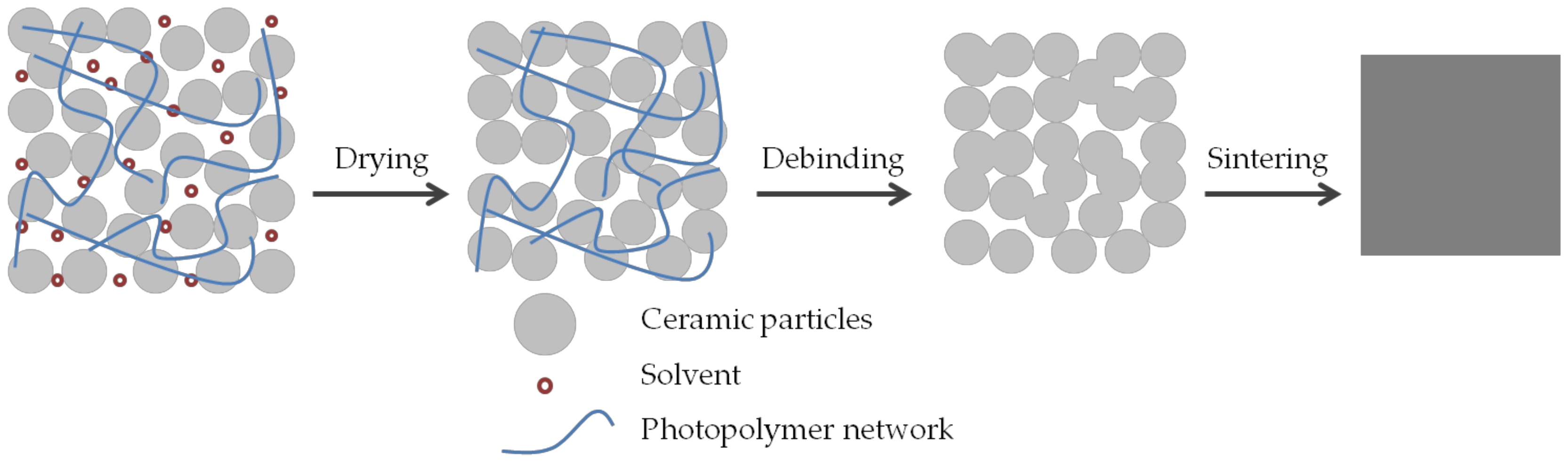

An essential step in ceramics engineering the first step in achieving a dense ceramic article is the processing and forming of raw materials into a consolidated near net shape.

Ceramic machining after sintering.

In order to tackle those problems machining can be carried out on the green ceramic to avoid the microcracks apparition and machining time is reduced thanks to an improvement of the powder preparation.

That is they can be turned milled drilled and saw cut without the need for diamond tooling.

Tunnel kilns and periodic kilns are commonly used for ceramics sintering firing.

Once the ceramic powder has been compacted and green machined if required the powder compact is usually around 50 of its final theoretical density.

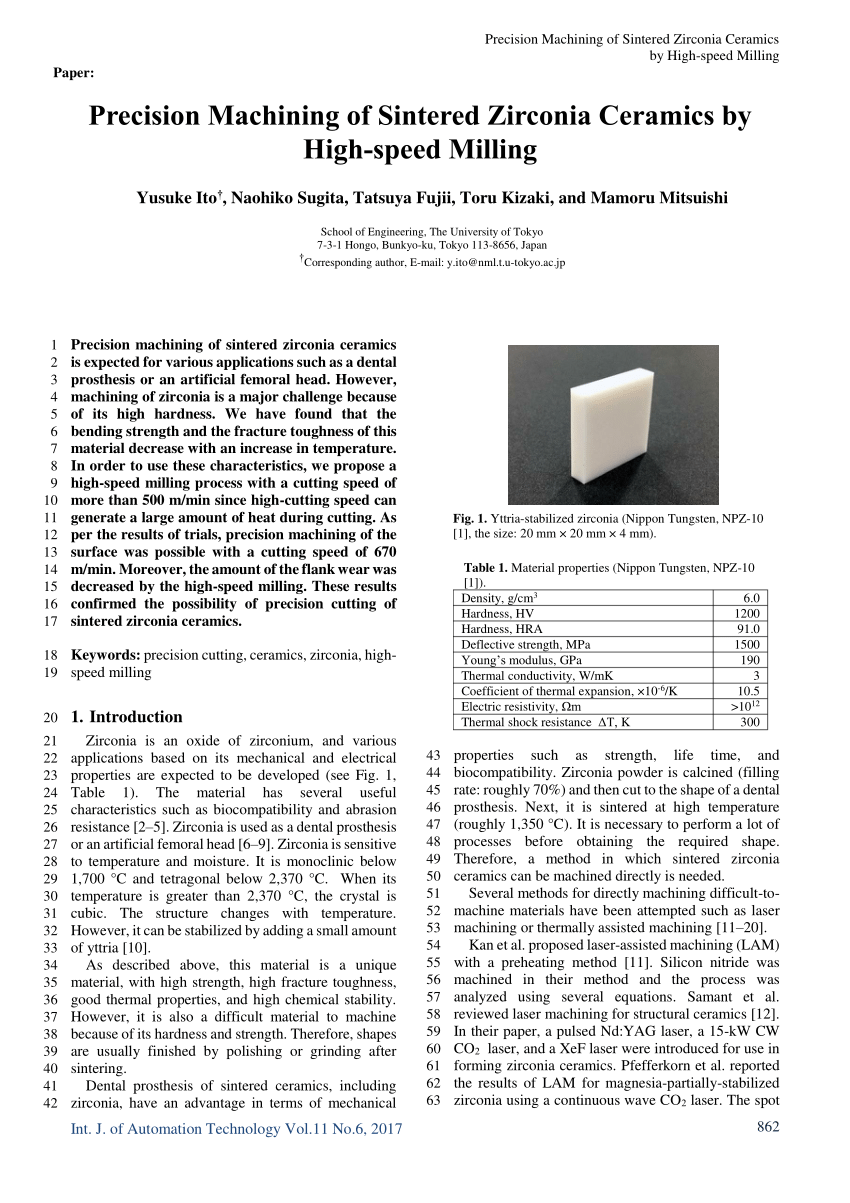

Post sintering machining of technical ceramics.

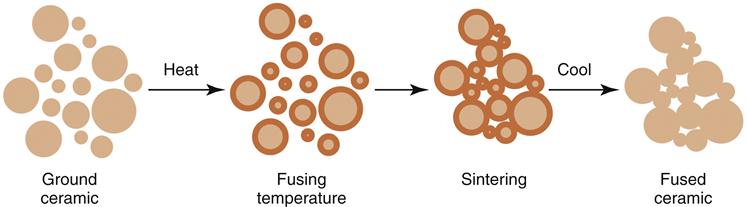

Lowering of free energyi.

Applying pressure decreases sintering time and the resulted porosity.

Laser machining of hard ceramic is difficult because the interaction of the laser beam with the material can lead to microcracks and surface modifications of the microstructure.

Machinable is a term used to describe ceramic materials that after sintering can be machined with traditional metalworking machine tools.

It covers the chip removal of advanced ceramics with a defined as well as an undefined cutting edge in the green state or the state after debindering and prefiring.

The machining is performed after the sintering cycle firing.

This process is used to produce prototypes or production runs of parts with a ratio of size to dimensional tolerance which could not be achieved by pressing or moulding.

Approximately half way through the sintering process the green ceramic reaches a biscuit state where almost all of the organic binder used in the original mix and pressing will have burnt off leaving an almost pure but not fully sintered material.

Full densification is achieved by sintering at temperatures up to 1800 c.

Sintering is a process as well as a state.

Sintering sintering is the process by which a powder compact is transformed to a strong dense ceramic body upon heating sintering could eliminate most pores in porous green body and compress residual pores and bring grain growth and improve binding among grains driving force for sintering.

This is generally achieved by pressing casting injection moulding or extruding a feedstock containing the ceramic powder which may subsequently be re worked via green machining.

Green machining is considered as an alternative to the use of cost intensive shaping tools.